Drawing Revision Numbering

When an asset is changed in the plant or out in the field, it's best practice to modify the existing engineering drawing to incorporate the changes. Once the edits have been made, the existing drawing is superseded and replaced by the new version. In a Drawing Management System, these kinds of changes are completed within a document workflow and often require engineering review and approval.

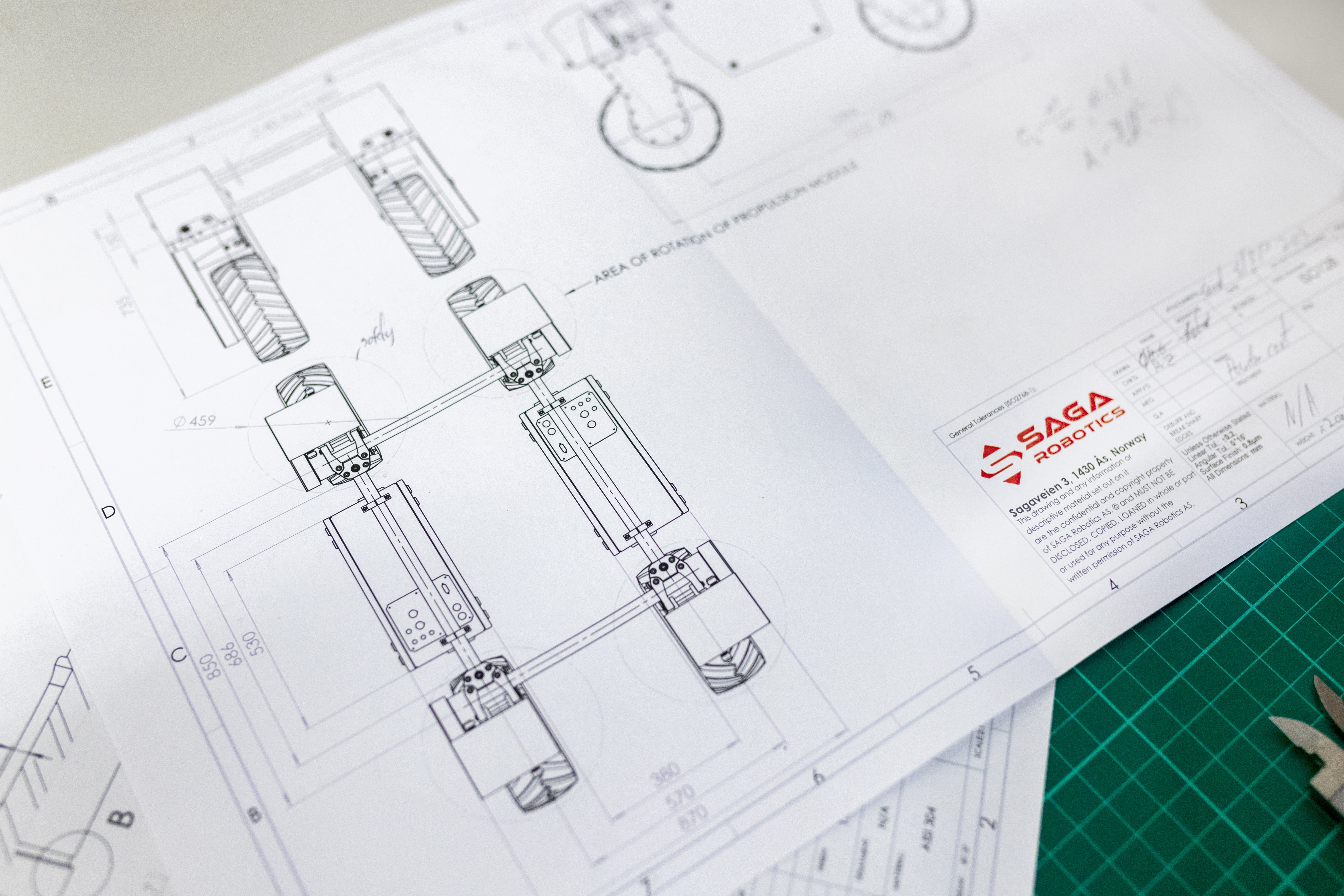

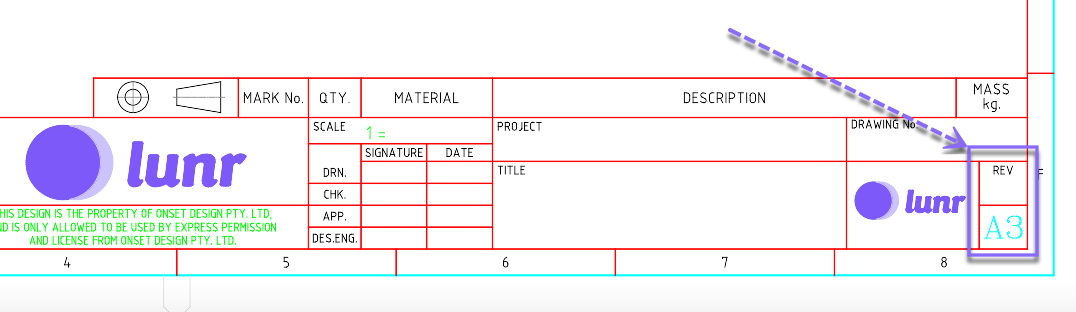

A common practice is to store the revision number inside the drawing title block and ensure that this revision is available to anybody viewing the file either within the system or externally. The drawing revision and drawing number make up a unique reference to a drawing - when making a change you need to know both the drawing number and the revision you are editing (generally the most recent revision).

There are many kinds of revision numbering schemes. One that we commonly see is to use alpha characters (A - Z) for the drawing revisions prior to when the drawing is released as-constructed, then move to a numeric numbering system for operations and maintenance changes. In these sequences, the letter "O" and the number "0" are removed from use to avoid confusion between the two.

There are many kinds of revision numbering schemes. One that we commonly see is to use alpha characters (A - Z) for the drawing revisions prior to when the drawing is released as-constructed, then move to a numeric numbering system for operations and maintenance changes. In these sequences, the letter "O" and the number "0" are removed from use to avoid confusion between the two.

As an example, drawing ME_501_A_001.dwg may start as revision A, and go through to revision D during the project phase. Once it's submitted as-built it would then move to revision 1. Revision numbering schemes like this are a useful method to ensure that everybody understands exactly where a drawing is at in its lifecycle and helps avoid costly errors and lost time.

One last thing to note is that during a single change cycle on a drawing, the file may go through a number of iterations as it's reviewed and adjusted to meet the project requirements. This is often referred to as a minor revision and is represented with an alpha.numeric format like A.1 or 1.1. This kind of minor revision scheme is consistent with the guidance of outlined in the UK BIM framework ISO 19650-2 around revision management within a CDE (Common Data Environment). For reference, the relevant section of the guide is 5.1 (Revision Control during Work in Progress - WIP).

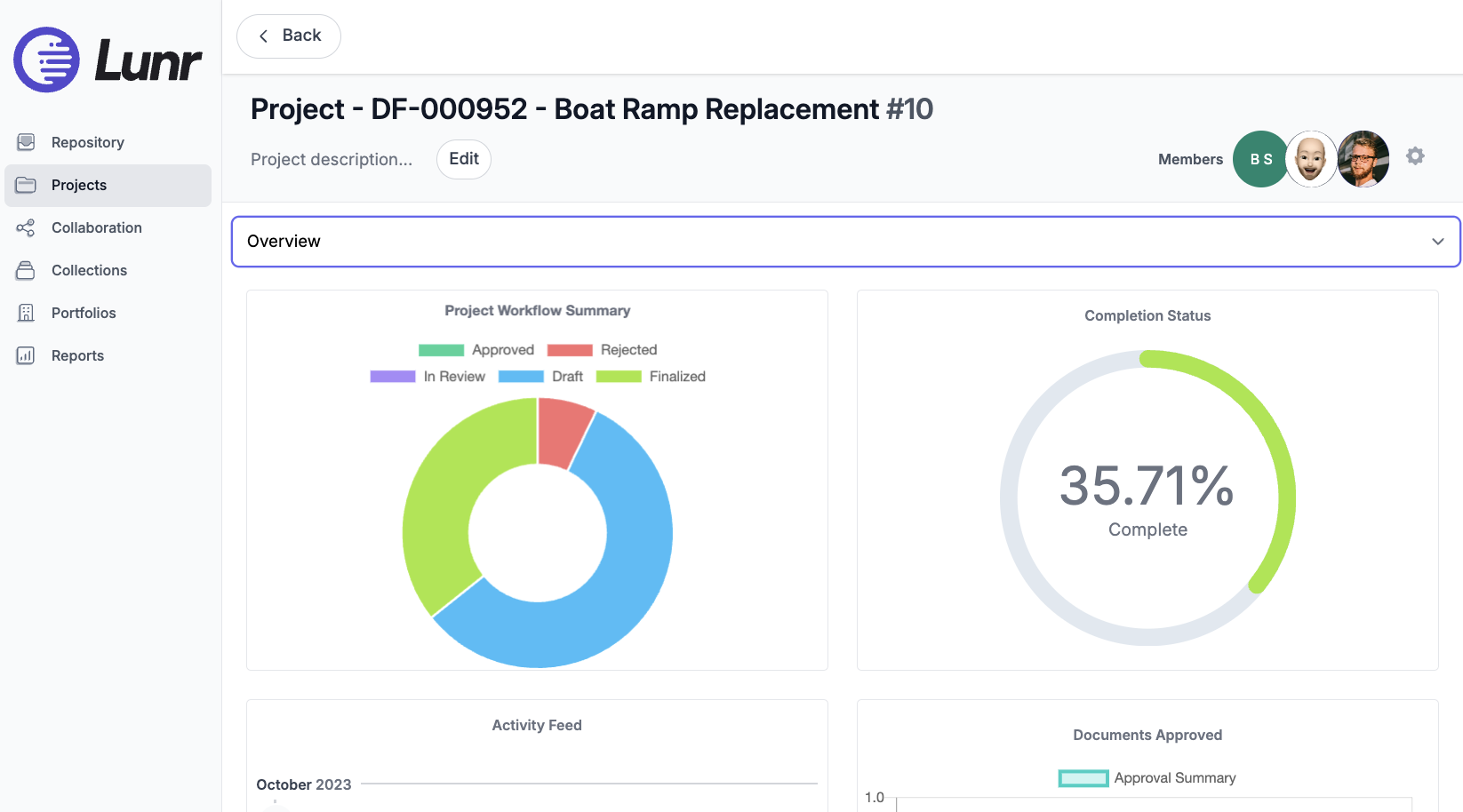

Drawing Management Systems such as Lunr and make it easier to follow best practices like this with engineering drawing specific features. Two features that help in this case are:

Automated revision numbering: Each time a drawing goes through workflow, the major and minor revision should be automatically incremented by the system to avoid the need for somebody to remember to make the change manually.

Title block integration: Ideally the revision should be synchronised back to the drawing title block automatically to ensure that the system and the drawing file are kept aligned.