Tackling Engineering Project Costs with Submittal Package Validation

How often do you receive a package of as-constructed drawings that complies 100% with the requirements outlined in your engineering drafting standard in the first submission? If you're like many people responsible for receiving and reviewing as-constructed drawings as a part of project completion, there is a good chance that a large proportion of received packages require some kind of re-work before they're accepted.

In my experience, this can be anywhere from 30% if you're lucky, to as high as 50 - 60% of drawings requiring rework to meet compliance. Much of the time, package quality checking, or quality assurance (QA) is manually performed by a document control team. When a package is rejected, there is not only additional cost involved in having the drawing corrections made, but also a secondary QA review step. This problem is compounded when the package doesn't reach 100% compliance by the second submission, and can sometimes involve 3 - 4 round trips before being accepted.

This situation introduces two major problems for engineering projects:

Cost blowouts due to drawing corrections: Multiple drawing corrections mean more drafting resource time is required to submit the package. It's often also difficult to get secure the relevant resource if they've already moved onto another project at that point in time.

Bottlenecks in document control: The increased QA demand can lead to project bottlenecks in document control departments due to the need for a higher number of QA review cycles than anticipated in the project.

Streamlining package submission - Validation

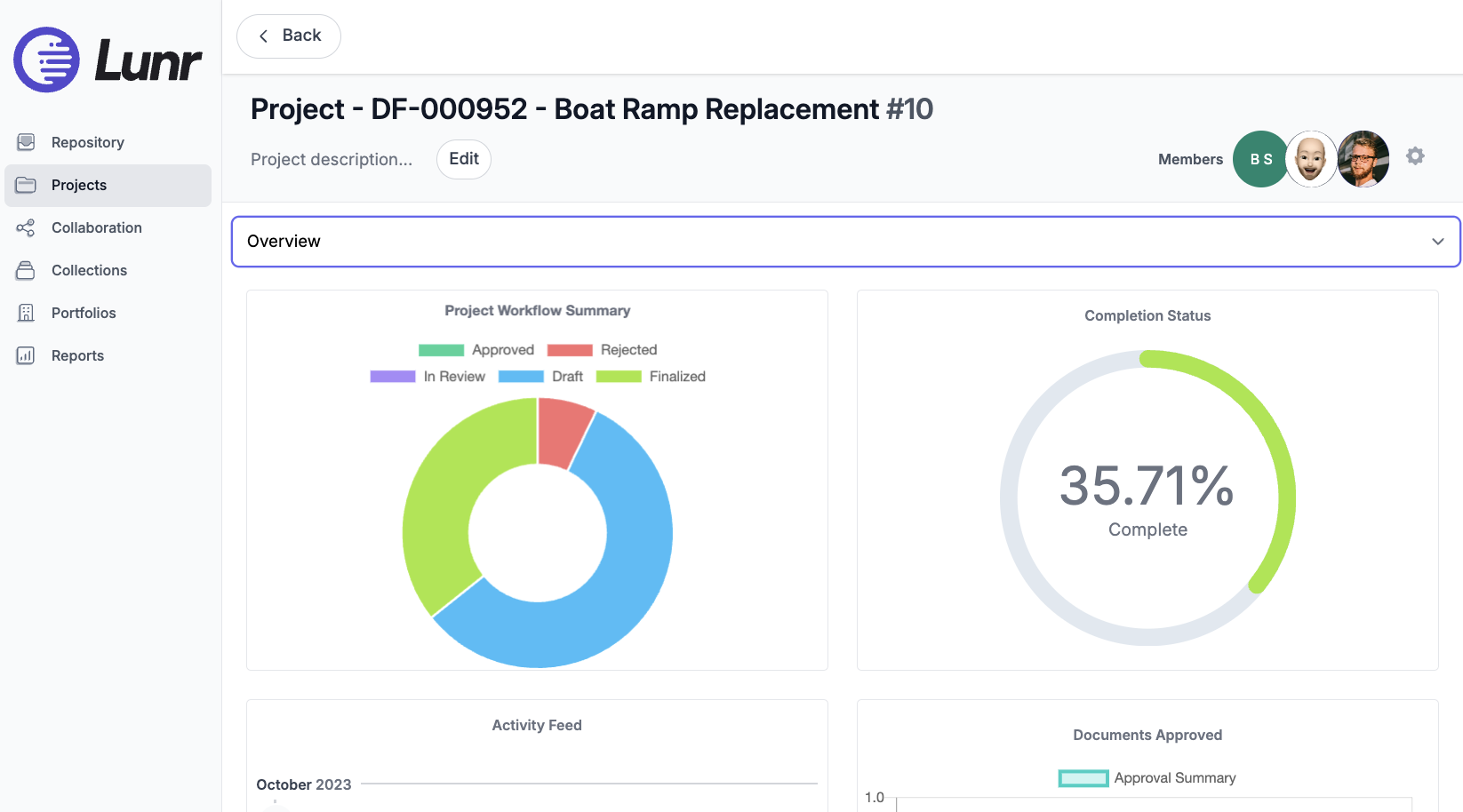

A fantastic way to solve both of the above problems is to introduce automated package validation into your submittal package workflow. The revised workflow is as follows:

Project member uploads the submittal package.

Validation checks are run over the package.

If the package is validated successfully and complies with the standard it is automatically imported into the system for QA review, otherwise, it's rejected back to the submitter for corrections.

This reduces the feedback loop from drawing handover to drawing acceptance and increases the likelihood that the original draftsperson is still on hand to make the required corrections. The earlier you can catch defects in the package, the more time you can potentially save.

High-value validation rules

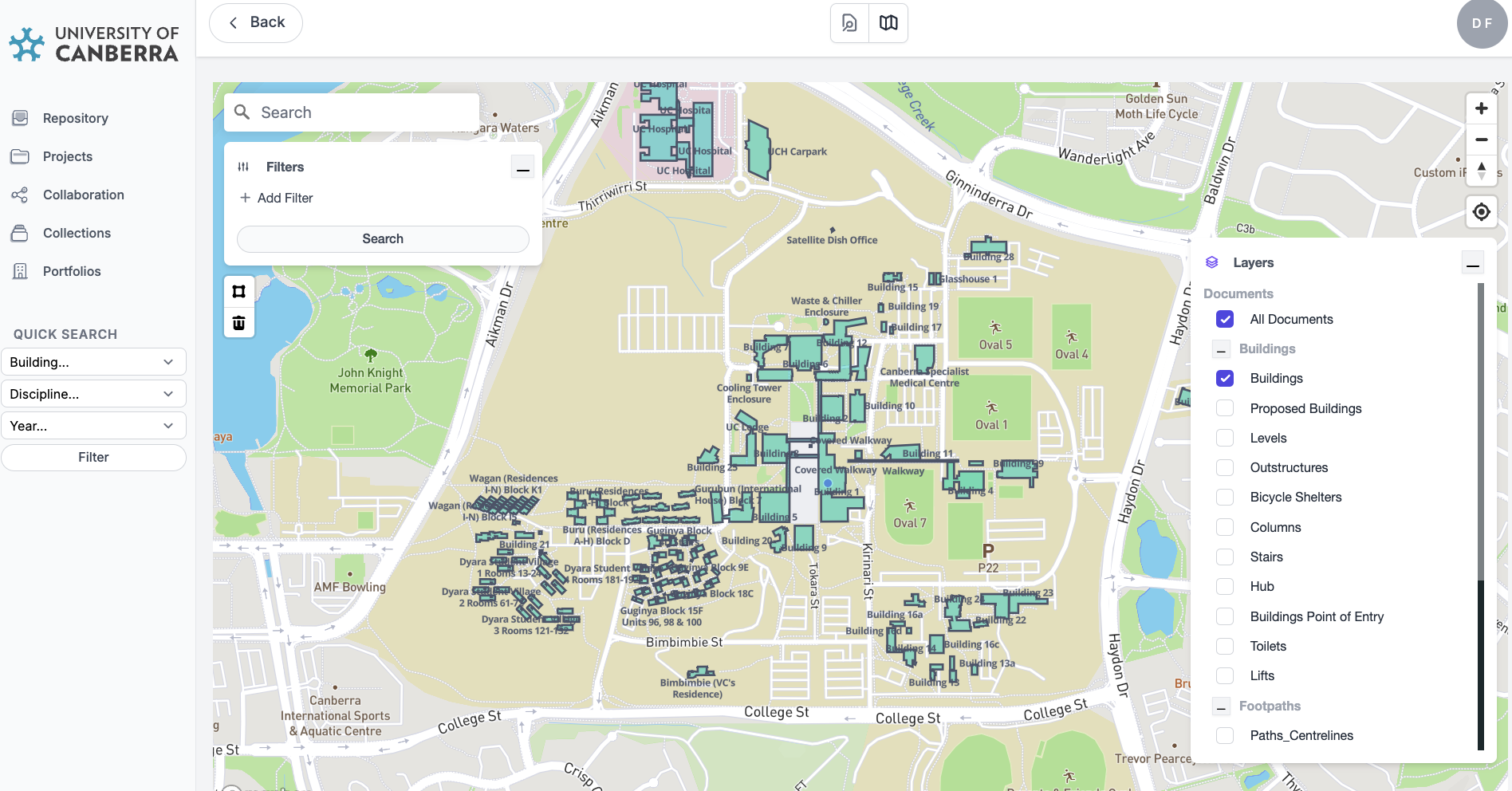

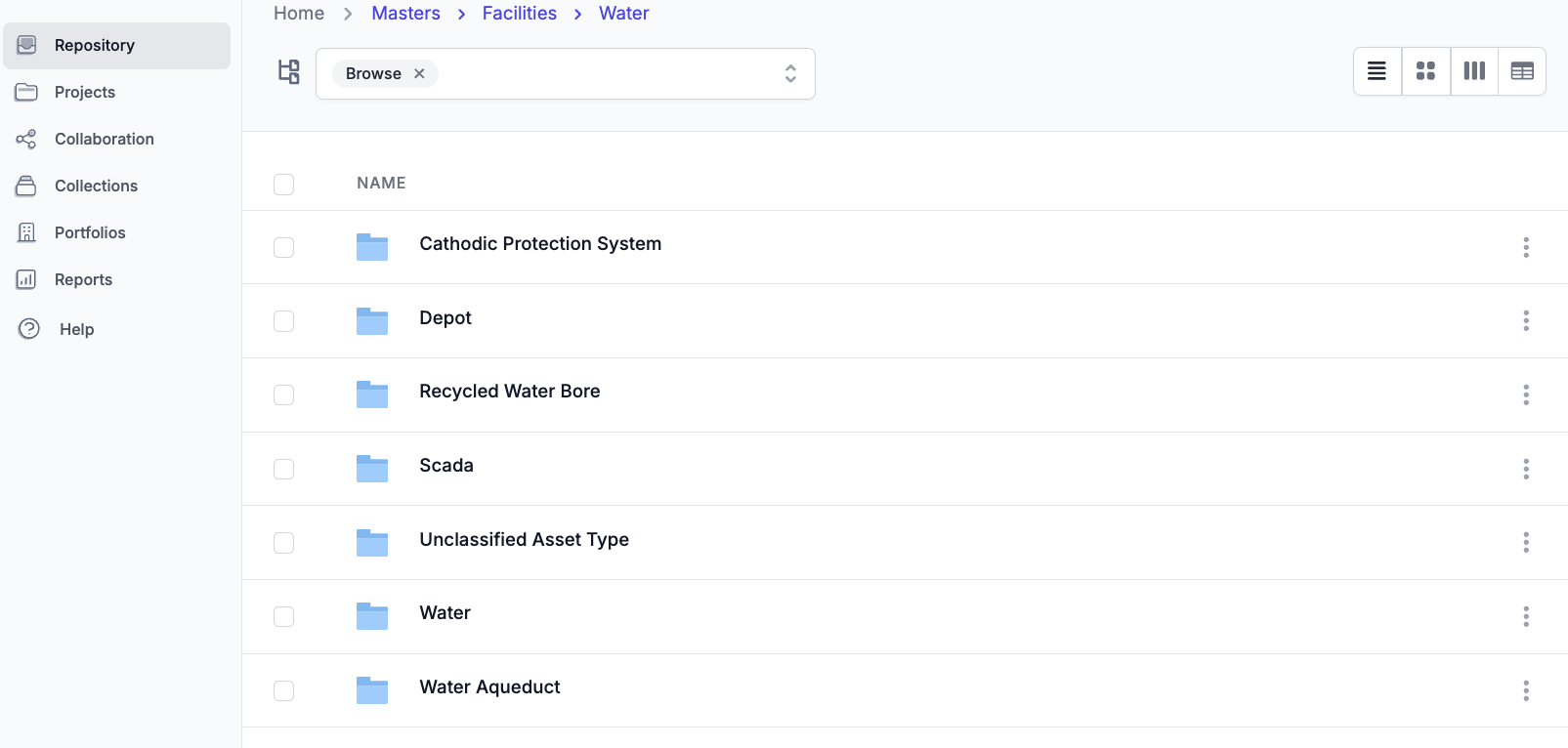

At the start of a DMS (Drawing Management System) implementation process, we review the CAD standard to determine which of the rules from the drafting standard can be automatically checked. Here are some of the common rules that we find add a lot of value to the process.

File name validation: Ensure that all files included in a submittal package match the rules outlined in the drafting standard.

XREF validation: Verify that there are no unbound x-refs missing from the package.

Title block validation: Verify that the asset owner's standard title block has been used.

Tag validation: Verify that each of the tags included in the title block complies with the asset drawing meta-data requirements.

Project document number validation: A common practice with large infrastructure projects is to pre-allocate a batch of document numbers (placeholders) in the document repository at the start of a project. This is a good way of ensuring that only valid file names are used and also avoids duplication. Repositories that use this strategy also benefit from a project document number validation rule, which verifies that all documents received have been allocated a placeholder in the given project.

It's never too late to add automated validation checking to your as-constructed documentation handover workflow. If you've got the benefit of starting fresh with a new system, it's worthwhile spending the time to get these rules right from the start. However even if you're working with an existing document repository, you can start taking small steps towards automated validation. Starting with a relaxed validation workflow, and gradually tightening the rules over time can also be a great way to ease project stakeholders into the process.